Global Distributed Enterprise Data Logistics

May 31, 2023

Introduction:

The customer, a leading global manufacturer of commercial vehicles, had a large on-prem data platform (Cloudera data lake), which had the inherent limitations of high dependency on data platform engineers, slow delivery, and performance challenge. This challenge impacted not only the manufacturing process, but also the global supply chain supporting Service and Manufacturing.

With operations spanning across multiple countries and a complex network of suppliers, manufacturers, and distributors, our customer faced numerous challenges in maintaining visibility and optimizing their global supply chain.

Challenges:

The company struggled with fragmented data sources, limited visibility into real-time supply chain events, and inefficient decision-making processes. This resulted in delays, increased costs, and missed opportunities for optimization. Intuitive recognized the need for a robust data management solution that could provide a holistic view of their supply chain, streamline operations, and enhance customer satisfaction.

The company faced several challenges during the technology integration process, and had the following requirements:

Technology Solutions

Intuitive Partnered with Azure to implement a cutting-edge data lake solution. The data lake served as a centralized repository that collected, stored, and processed vast amounts of structured and unstructured data from various sources within the company's supply chain ecosystem. Leveraging cloud-based technologies, the data lake ensured scalability, flexibility, and real-time access to critical supply chain data.

Implementation Strategy

Intuitive successfully integrated the following innovative technologies:

- AZURE Native Cloud and Services

- Hybrid Cloud Ingestion Framework (Batch and Streaming Data Paths)

- Databricks (Transformation and Delta Table Staging)

- Azure ML Studio

- Azure Synapse and Power BI

- Source to Destination Data Orchestration pipelines

Intuitive’s team collaborated closely with our customer to understand their unique supply chain requirements. We conducted a comprehensive assessment of existing data sources, including ERP systems, IoT sensors, logistics platforms, and customer feedback channels. Based on this analysis, Intuitive designed a data lake architecture that allowed seamless integration of diverse data streams while ensuring data quality and security.

Key Features and Benefits:

- Data Integration and Consolidation: The data lake enabled the team to bring together data from multiple systems and sources, including inventory management, logistics, demand planning, and customer feedback. This integration provided a single source of truth for supply chain data, eliminating data silos and enabling cross-functional visibility.

- Real-time Analytics and Insights: With the data lake's powerful analytics capabilities, our customer gained real-time insights into their supply chain performance. Advanced analytics models and machine learning algorithms helped identify bottlenecks, predict demand fluctuations, optimize inventory levels, and improve forecasting accuracy.

- Enhanced Collaboration: The data lake facilitated collaboration across different departments, geographies, and stakeholders. Teams could access relevant data and reports, fostering data-driven decision-making and enabling proactive supply chain management.

- Predictive Maintenance: By analyzing IoT sensor data from production lines and transportation fleets, Intuitive implemented predictive maintenance strategies. This proactive approach reduced equipment downtime, improved asset utilization, and increased overall operational efficiency.

- Customer Satisfaction and Retention: The data lake played a crucial role in understanding customer needs and preferences. By analyzing customer feedback, sentiment analysis, and purchase patterns, flexibility was delivered to tailor their products and services, resulting in higher customer satisfaction and increased loyalty.

Results and Impact

The implementation of the data lake solution revolutionized our customers supply chain management. The company experienced the following outcomes:

- Improved Supply Chain Visibility: The data lake provided real-time visibility into the entire supply chain, enabling proactive decision-making and rapid response to disruptions or delays.

- Cost Reduction: By optimizing inventory levels, streamlining logistics operations, and minimizing downtime through predictive maintenance, We achieved significant cost savings across their supply chain.

- Enhanced Operational Efficiency: Streamlined processes, automated workflows, and data-driven insights led to improved operational efficiency, reduced lead times, and increased throughput.

- Increased Customer Satisfaction: By leveraging the data lake's capabilities to better understand customer needs and preferences, Intuitive’s solution successfully improved product quality, delivery speed, and customer service, resulting in higher customer satisfaction and increased customer loyalty.

Lessons Learned

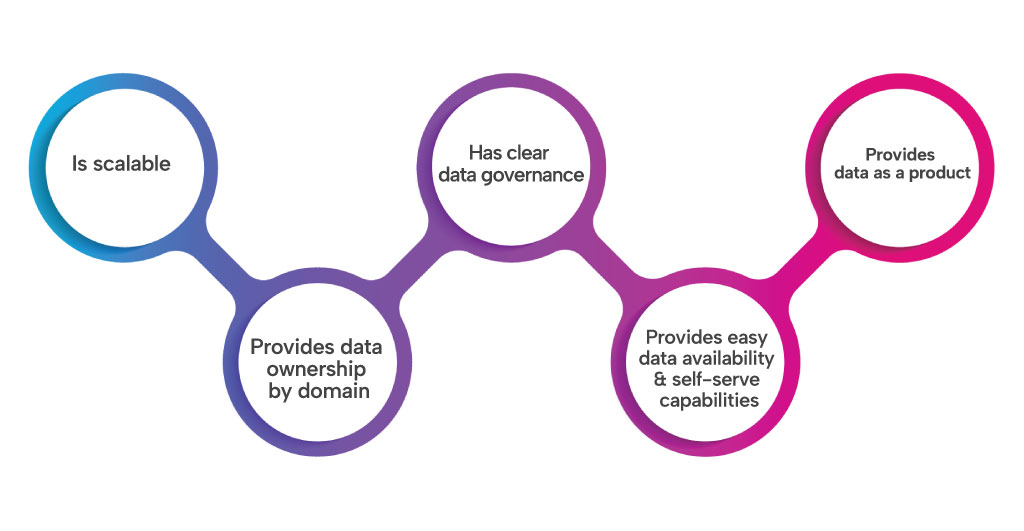

A data mesh project is an innovative approach to managing data in an organization that emphasizes decentralization and domain-driven ownership. Here are five lessons that can be learned from a data mesh project:

- Clear communication and collaboration are critical: A data mesh project requires extensive collaboration across departments and teams. Clear communication and collaboration between these teams are essential to ensure that everyone is working towards the same goals and that the project is successful.

- Domain-driven design is essential: In a data mesh project, data ownership is assigned to different domains or departments, each responsible for their own data products. Therefore, it is crucial to apply domain-driven design principles to ensure that data products are aligned with the needs of the domain and that they are of high quality.

- Data governance is crucial:Data governance is critical in a data mesh project to ensure that data is managed consistently across domains and departments. This includes setting up policies, procedures, and standards to ensure data quality, security, and compliance.

- Technology is an enabler, not a solution:Technology is essential to support the data mesh project, but it is not the solution itself. The right tools and platforms must be chosen to support the decentralized approach to data management, but they must be implemented and used effectively to achieve the desired outcomes.

- Continuous learning and improvement are necessary: A data mesh project is not a one-time project, but an ongoing journey of continuous learning and improvement. The project team must continuously assess and adapt their approach, processes, and technologies to ensure that they are meeting the needs of the organization and delivering value over time.

Conclusion

The adoption of the data lake solution revolutionized our customers global supply chain management, delivering tangible benefits across various aspects of their operations. With improved visibility, streamlined processes, and data-driven decision-making, they experienced significant cost reductions, enhanced operational efficiency, and increased customer satisfaction. The data lake became a central hub for real-time insights, enabling proactive measures, predictive maintenance, and personalized customer experiences. As a result, the solution solidified our customers position as a leader in supply chain management, driving growth, and achieving sustainable success in the highly competitive global market.